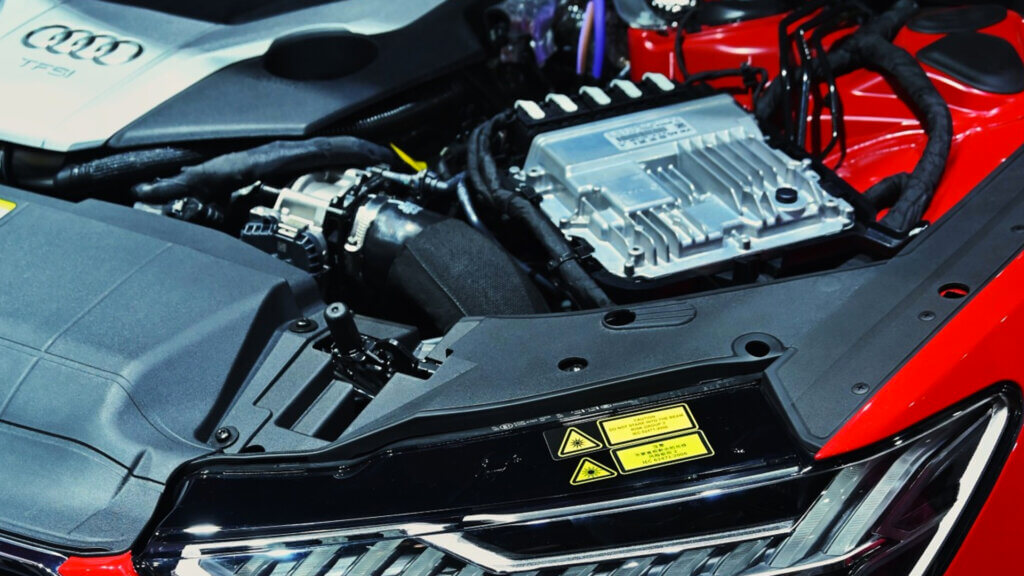

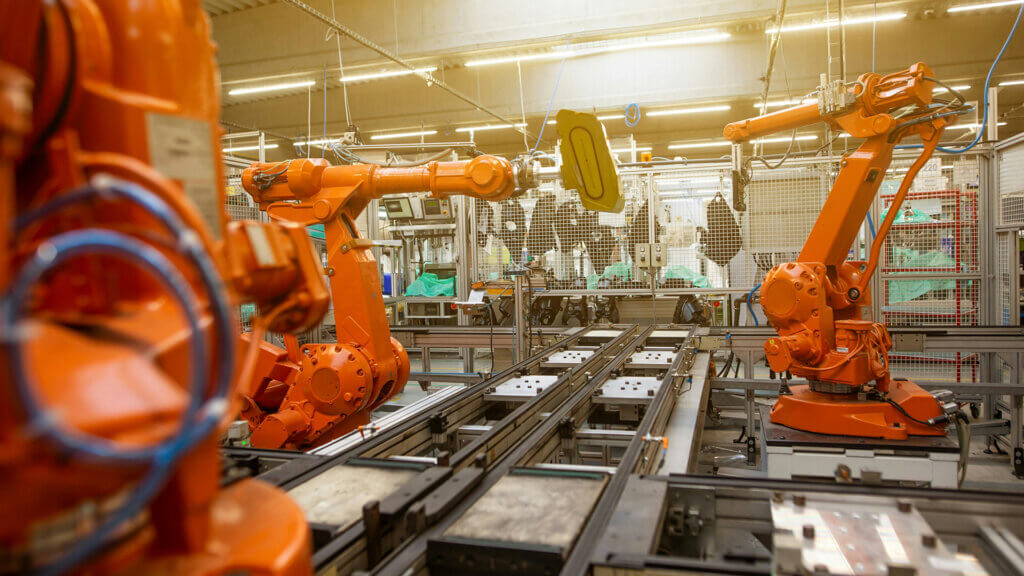

Rivets serve as a practical solution for joining materials without the need for welding, adhesives, or specialised tools. While applicable in various sectors, automotive rivets specifically warrant attention for their diverse applications in vehicle construction and repair.

Applications in Automotive Repairs

Automotive rivets find utility in structural repairs like affixing slip-on panels, attaching plastic bumper covers, and executing specialised bodywork. They also excel in securing finished materials such as painted surfaces.

The Mechanics of Blind Rivets

Comprising a rivet body and a mandrel, blind rivets operate by inserting the rivet body into a hole in the materials, followed by the use of a rivet gun to pull the mandrel. This action causes the rivet body to expand, creating a secure connection. Blind rivets, including popular variations like Metal Blind Pop Rivets and Nylon Blind Pop Rivets, offer strength, security, and accessibility advantages, requiring access from only one side of the materials.

Materials & Types

Automotive rivets come in various materials and combinations to suit different applications. Common combinations include aluminium/aluminium, aluminium/steel, copper, nylon, stainless/stainless, stainless/steel, and steel/steel. Rivet types encompass open-end and closed-end varieties, each offering distinct advantages in strength and application versatility.

Head Styles & Sizing

Rivet head styles such as Dome Head, Large Flange, and Countersunk cater to different mounting requirements. Selecting the appropriate rivet involves considering factors like diameter, grip range, head style, flange size, and corrosion resistance. Rivet diameter influences strength, with larger diameters providing higher shear and tensile strength.

Speciality Rivets for Unique Needs

Speciality rivets like Peel Split, T-Rivets, Leg Retaining, and Self-Piercing offer tailored solutions for specific material characteristics and application demands. Peel Split rivets, for instance, enhance support in brittle or soft materials, while Self-Piercing rivets expedite joining processes in sheet materials without the need for pre-drilled holes.

Get In Touch With Auto-Fasteners Today

Auto-Fasteners exists to connect with its automotive customers as a partner, not just a parts supplier. We aim to understand the problems you are facing, to collaborate with you and to help you solve that problem. Get in touch with us via our online contact form or by giving us a call at 01926 814600 to discuss your automotive fastener requirements.