A deep dive into the relationship between torque and fastener tightness.

The relationship between torque and fastener tightness is fundamental in automotive engineering and plays a crucial role in various applications. Understanding this relationship is essential for ensuring that fasteners are properly tightened to achieve specific objectives such as safety, reliability, and structural integrity.

Here’s how torque and fastener tightness are related:

Torque is a Measure of Tightness:

Torque is a quantifiable measurement of the rotational force applied to a fastener, such as a bolt or nut, during the tightening process. It’s typically measured in units like Newton metres (N-m) or foot-pounds (ft-lb).

The amount of torque applied directly influences the tightness of the fastener. In general, the greater the torque applied, the tighter the fastener becomes, assuming all other factors remain constant.

Torque-Clamp Relationship:

The relationship between torque and the clamping force applied by a fastener can be described by the equation: Clamping Force = Torque / Distance where “Distance” is the lever arm or the effective length at which the torque is applied.

The above equation illustrates that clamping force and torque are inversely proportional. In other words, if you apply more torque to a fastener with a fixed lever arm, you will increase the clamping force, making the fastener tighter.

Tension & Compression:

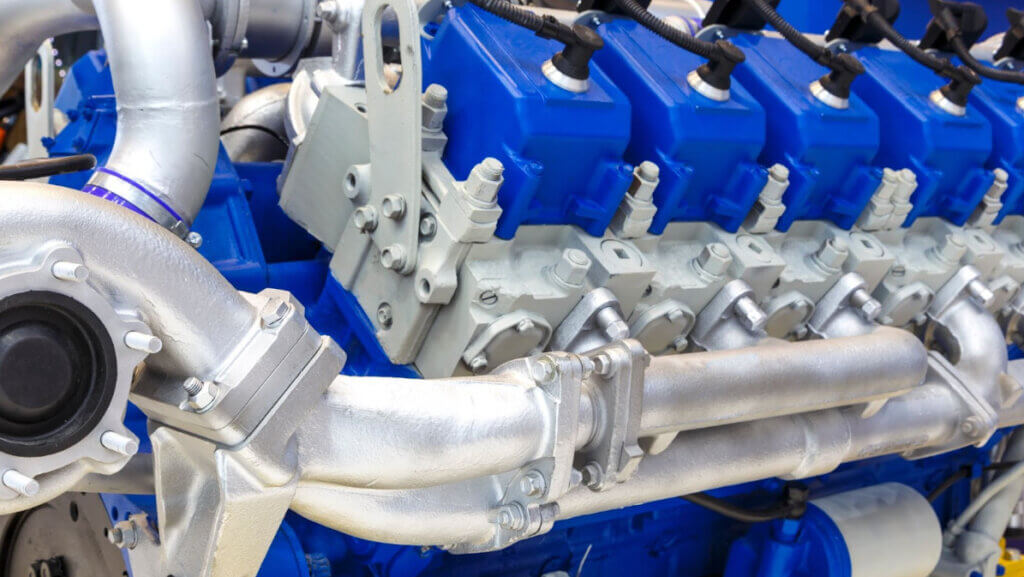

When a fastener is tightened, it creates tension (stretching) in the fastener or the materials it joins. This tension generates a clamping force that holds the components together. In the case of bolts, this clamping force is crucial for maintaining structural integrity and preventing relative motion between the joined parts.

It’s important to note that fasteners can be designed to work in tension (as in most bolts and screws) or in compression (as in some types of fasteners). In both cases, the relationship between torque and tightness holds true.

Torque Specifications:

Engineers and manufacturers determine specific torque values for different fasteners and applications. These torque specifications are based on factors such as material properties, thread pitch, fastener size, and the intended purpose of the connection.

Following these torque specifications is critical for ensuring that fasteners are tightened to the right level. Over-tightening can lead to damage or failure, while under-tightening can result in loose connections.

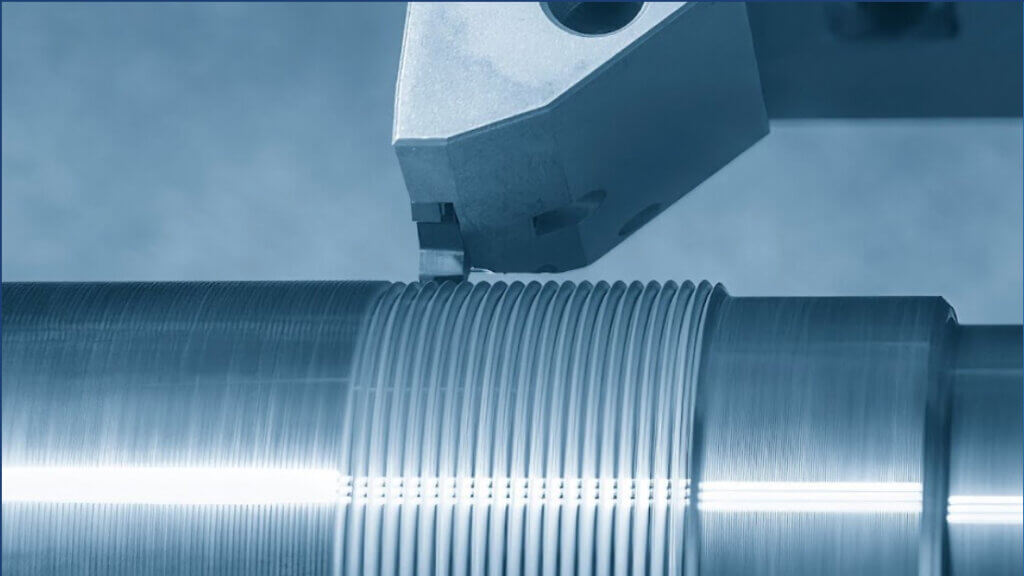

Friction & Thread Pitch:

The friction between the fastener threads and the materials being joined, as well as the thread pitch, plays a role in the relationship between torque and tightness. High friction or fine thread pitches can require more torque to achieve the same level of tightness as compared to low friction or coarse threads.

The relationship between torque and fastener tightness is a key principle in mechanical engineering. By applying the appropriate amount of torque to a fastener, the desired level of clamping force is generated, ensuring that components are securely held together. It is important to follow torque specifications and consider factors like friction and thread pitch to achieve the correct tightness while avoiding over-tightening or under-tightening, which can lead to various issues in mechanical assemblies.

Get In Touch With Auto-Fasteners Today

Auto-Fasteners exists to connect with its automotive customers as a partner, not just a parts supplier. We aim to understand the problems you are facing, to collaborate with you and to help you solve that problem.

Get in touch with our team via our online contact form or by giving us a ring at 01926 814600!