In the manufacturing of automotive fasteners, the choice between hot forging and cold forging plays a crucial role in determining the properties, quality, and performance of the final product. Let’s explore how hot forging and cold forging differ, along with the advantages each method offers specifically in the context of automotive fastener production:

Hot Forging for Automotive Fasteners

Temperature

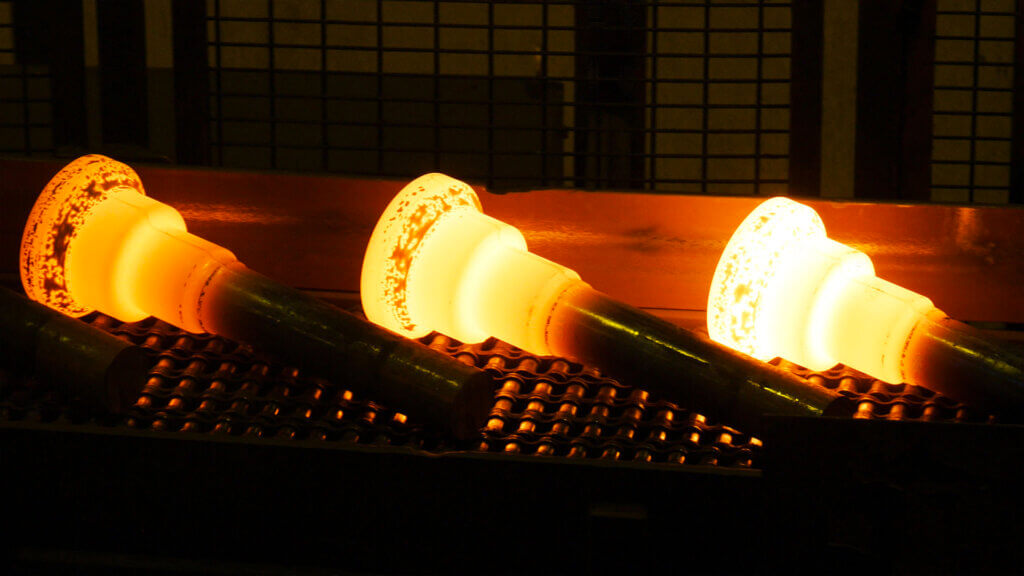

- Process: Hot forging involves heating the metal to high temperatures, typically above its recrystallisation temperature.

- Advantages: Hot forging is advantageous for automotive fasteners because it allows for the deformation of materials like steel and alloy steel at elevated temperatures, making them more malleable. This process is suitable for creating larger and more complex fastener shapes.

Material Flow

- Process: In hot forging, the heated material experiences significant plastic deformation, allowing it to flow more easily into the desired shape.

- Advantages: The material flow in hot forging results in a more uniform and refined grain structure, contributing to improved mechanical properties and strength in the final fastener.

Reduced Energy Consumption

- Process: Despite the energy-intensive heating process, hot forging can be energy-efficient due to the reduced force required for deformation.

- Advantages: The reduced forging forces lead to less strain on the equipment, potentially resulting in lower overall energy consumption compared to cold forging.

Cold Forging for Automotive Fasteners:

Temperature:

- Process: Cold forging is performed at or near room temperature without the need for pre-heating the metal.

- Advantages: For automotive fasteners, cold forging is advantageous because it capitalises on the material’s natural hardness at lower temperatures, providing strength without the need for additional heat treatment.

Material Hardening:

- Process: Cold forging induces work hardening, strengthening the material as it is deformed.

- Advantages: The work-hardening effect in cold forging enhances the tensile strength and hardness of the fastener, making it suitable for applications where high strength is critical, such as in high-stress areas of automotive components.

Precision and Tighter Tolerances:

- Process: Cold forging allows for greater precision and tighter tolerances due to less material flow during deformation.

- Advantages: In automotive fastener production, the precision achieved through cold forging can reduce the need for secondary machining operations, contributing to cost savings and more efficient manufacturing processes.

Surface Finish:

- Advantages: Cold forging often results in a smoother surface finish, reducing the need for additional finishing processes. This can be advantageous for automotive fasteners where surface quality is important for aesthetics and corrosion resistance.

In summary, the choice between hot forging and cold forging in automotive fastener production depends on factors such as material type, the complexity of the fastener design, desired mechanical properties, and cost considerations. Both methods offer distinct advantages, and manufacturers may employ a combination of these processes to meet specific requirements in the production of high-quality automotive fasteners.

Get In Touch With Auto-Fasteners Today

Auto-Fasteners exists to connect with its automotive customers as a partner, not just a parts supplier. Our aim is to really understand the problems you are facing, to collaborate with you and to help you solve that problem.

Get in touch with our expert team today by giving us a ring at 01926 814600 or via our online contact form to discuss your automotive fastener requirements.